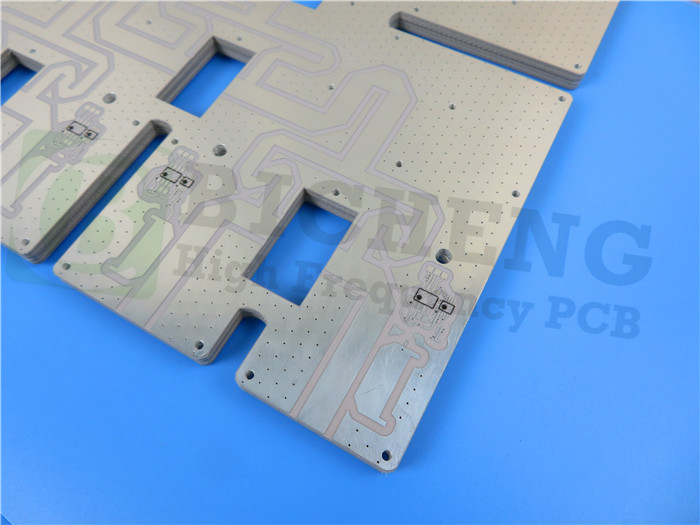

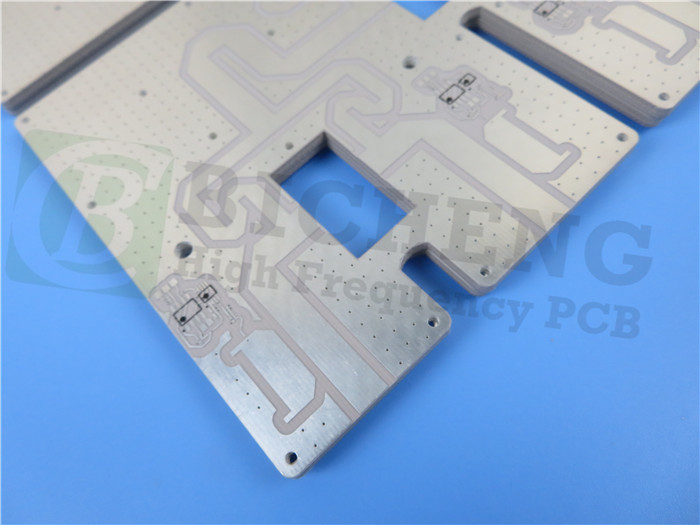

RO3206 High Frequency PCB DK 6.15 – Rogers RO3206 RF Circuits for 5G, Automotive, and Wireless Applications

(Printed Circuit Boards are custom-made products, the picture and parameters shown are just for reference)

Introduction

The Rogers RO3206 high-frequency PCB materials are engineered laminates containing ceramic fillers reinforced with woven fiberglass. These materials are designed to deliver outstanding electrical performance and mechanical stability while remaining competitively priced. An extension of the RO3000 series, the RO3206 offers enhanced mechanical stability.

With a dielectric constant of 6.15 and a low dissipation factor of 0.0027, the RO3206 materials provide an extended frequency range suitable for applications requiring high-frequency performance, exceeding 40 GHz.

The RO3206 laminates merge the benefits of non-woven PTFE laminates—such as surface smoothness for fine line etching tolerances—with the rigidity of woven-glass PTFE laminates. They can be easily fabricated into printed circuit boards using standard PTFE processing techniques.

Manufactured under an ISO 9002 certified quality system, RO3206 laminates ensure consistent quality and adherence to stringent manufacturing standards.

Key Features and Benefits

The RO3206 PCB offers several key features and benefits:

Woven Glass Reinforcement: Enhances rigidity, simplifying handling during fabrication and assembly.

Uniform Electrical and Mechanical Performance: Ideal for complex multi-layer high-frequency structures, ensuring consistent performance throughout the design.

Low Dielectric Loss: Minimizes signal loss and distortion, enabling excellent high-frequency performance.

Low In-Plane Expansion Coefficient: Matched to copper, compatible with epoxy multi-layer board hybrid designs for reliable surface-mounted assemblies.

Excellent Dimensional Stability: Maintains consistent dimensions during manufacturing, leading to high production yields.

Cost-Effective Pricing: Provides economical solutions for volume manufacturing, making it a cost-efficient choice for large-scale production.

Surface Smoothness: Features a smooth surface for finer line etching tolerances, allowing for precise circuit design and fabrication.

Our PCB Capability (RO3206)

| PCB Capability (RO3206) | |

| PCB Material: | Ceramic-filled Laminates Reinforced with Woven Fiberglass |

| Designation: | RO3206 |

| Dielectric constant: | 6.15 |

| Dissipation factor | 0.0027 |

| Layer count: | Single Sided, Double Sided, Multi-layer PCB, Hybrid PCB |

| Copper weight: | 1oz (35µm), 2oz (70µm) |

| Dielectric thickness | 25mil (0.635mm), 50mil (1.27mm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Yellow, Red etc. |

| Surface finish: | Immersion gold, HASL, Immersion silver, Immersion tin, ENEPIG, OSP, Bare copper, Pure gold plated etc.. |

Typical Applications

RO3206 PCBs are widely used in various industries, including:

1.Automotive collision avoidance systems

2.Automotive global positioning satellite antennas

3.Base station infrastructure

4.Direct broadcast satellites

5.Datalink on cable systems

6.LMDS (Local Multipoint Distribution Service) and wireless broadband

7.Microstrip patch antennas for wireless communications

8.Remote meter readers

9.Power backplanes

10.Wireless telecommunications systems

Rogers RO3206 Data Sheet

| Typical Values | |||||

| Property | RO3206 | Direction | Unit | Condtion | Test Method |

| Dielectric Constant, εr Process | 6.15± 0.15 | Z | - | 10 GHz 23°C | IPC-TM-650 2.5.5.5 Clamped Stripline |

| Dielectric Constant, εr Design | 6.6 | Z | - | 8 GHz - 40 GHz | Differential Phase Length Method |

| Dissipation Factor, tan δ | 0.0027 | Z | - | 10 GHz 23°C | IPC-TM-650 2.5.5.5 |

| Thermal Coefficient of εr | -212 | Z | ppm/°C | 10 GHz 0-100°C | IPC-TM-650 2.5.5.5 |

| Dimensional Stability | 0.8 | X,Y | mm/m | COND A | ASTM D257 |

| Volume Resistivity | 103 | MΩ•cm | COND A | IPC 2.5.17.1 | |

| Surface Resistivity | 103 | MΩ | COND A | IPC 2.5.17.1 | |

| Tensile Modulus | 462 462 |

MD CMD |

kpsi | 23°C | ASTM D638 |

| Water Absorption | <0.1 | - | % | D24/23 | IPC-TM-650 2.6.2.1 |

| Specific Heat | 0.85 | J/g/K | Calculated | ||

| Thermal Conductivity | 0.67 | - | W/m/K | 80°C | ASTM C518 |

| Coefficient of Thermal Expansion (-55 to 288 °C) | 13 34 |

X,Y, Z |

ppm/°C | 23°C/50% RH | IPC-TM-650 2.4.41 |

| Td | 500 | °C | TGA | ASTM D3850 | |

| Color | Tan | ||||

| Density | 2.7 | gm/cm3 | |||

| Copper Peel Strength | 10.7 | pli | 1 oz. EDC After Solder Float | IPC-TM-2.4.8 | |

| Flammability | V-0 | UL 94 | |||

| Lead Free Process Compatible |

YES | ||||